PART I Project Evaluation

1. Technical Characteristic PLC+touch screen, making the operation easy. Automatic malfunctionalarmwith selfdiagnosis, making the malfunction clear at a glance. Center input die head, eliminating the knit line completely and makingit easyto change the material and color. Double linear rolling motion guider in moving, opening and closingmold, making the clamping force equally distributed, so the cut is smoother. Control the hydraulic system with imported proportional valve, ensuringtheaction steady, accurate and energy saving. High speed and efficient plasticizing system, mixing well and ensuringthe

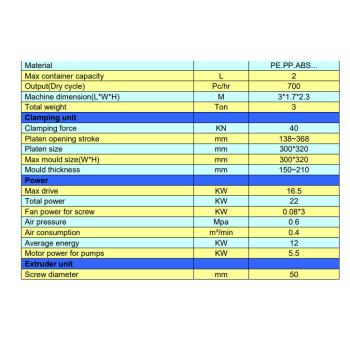

2. Basic Specification Die head: vertical type advanced structure. Extrusion system: adopting imported automatic temperature control device, hardened gear box and imported frequency convertor control screwspeedtoreach motor stepless speed regulation. Clamping system: adopting stable liner guide way device. Blowing device: adjustable upper and down blowing needle device. Parison control: Jeffren or MOOG wall thickness control system Hydraulic system: the full set of hydraulic systemadopts importedcomponents, using proportional control loop. Electric system: adopting full set programmable controller(Japan) andworldfamous electric parts.

3. Offer Detaila) Technical ProcessMaterial → Load material → Heat material → Extrusion →Blowmolding→Product

Favorite Failure!

Favorite Failure!